Mould - brief description

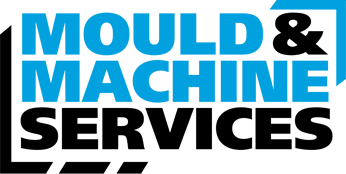

The mold consists of two main parts, the mould head and the mold frame. The shape of the final product is determined by wear plates in the mould frame; the mould head presses the product from the top using tampers.

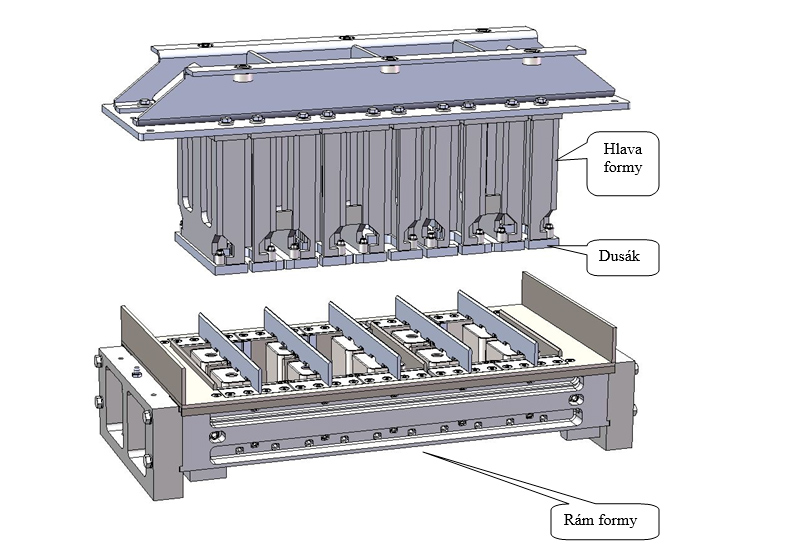

The shape of the product is formed by the side plates and the cross plates or cavities (do not have to be part of the mould) and are assembled in the mould frame.

Space intended for filling with concrete, which is around the cavities and the plates, is forming the exact shape of the final product.

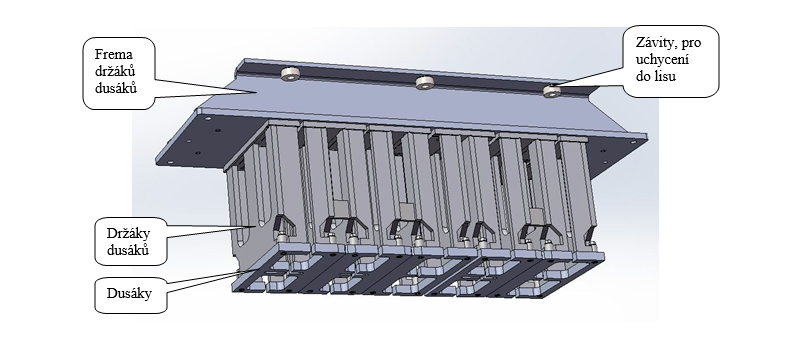

The head of the mould consists of tampers used to press the product and forms the upper part of the product. The tamper holders which must enable the tampers to pass through the frame of the mould. The frame weldment of the tampers holder allows mounting the mould head into the press and interconnects all holders of the tampers.

The sides and side edges of the mould are locked into each other into an exact position and are joined with screws.

After adjusting clearances between the tampers and the plates or cavities, both parts of the mould are connected together for transfer using a frame transfer carrier. The exact position between the head and the frame of the mould is secured by centering pins. The frame transfer carrier is not part of the mould when the mould is in the press, it is only used to secure the position during the transfer.